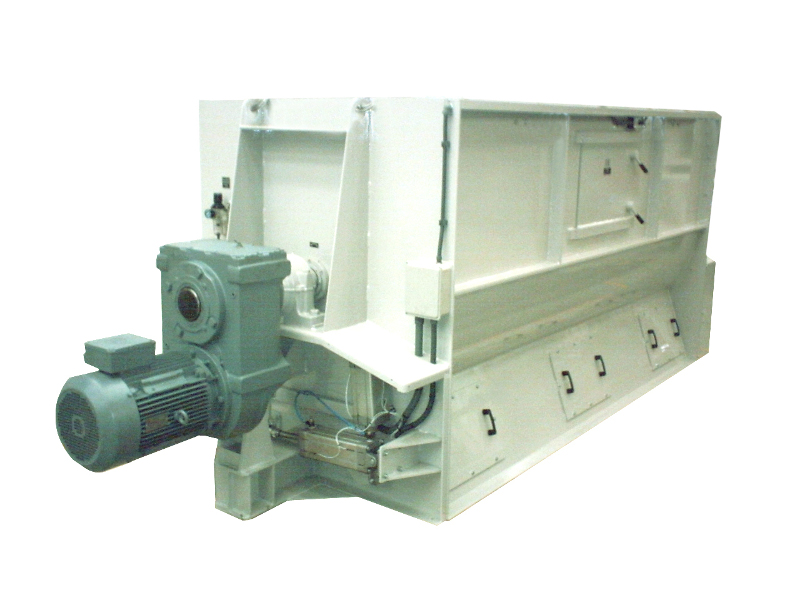

Ribbon mixer

Capacity

Capacities range from 1,000 litres to 6,000 litres, guaranteeing a solution for any production need.

- Effective mixing time: 4 minutes.

- Production: 10 mixtures / hour.

Construction

The design of the BHT series horizontal blade mixers enables optimum homogenisation and mixture of a wide variety of products. Depending on the nature of the products to be mixed, the blades may be made from carbon steel, stainless steel or with Teflon coating.

The mixing chamber features a cylindrical casing finished with two parallel flaps. Inside the casing is an axle, to which an inner and outer double spiral arm is attached. This ensures a homogenous mixture and complete ejection of the product, thereby preventing contamination in successive mixtures.

The axle is mounted on two roller bearings, receiving direct movement from a gearbox. This prevents energy loss and maintenance expenses on pinion and chain transmissions.

The product is ejected through a central chute with scrapers and a foldable pneumatic flap.

Addition of fats and oil

On request from the customer, high-pressure heated injectors can be installed to incorporate all kinds of fats and oleins (up to 8%), producing a micronized effect.

Weighing system

The mixer may be mounted on electronic load cells with a dosing system and computerized control for continuous production management.

Measures & Models

| Model | Total Capacy | Operating Capacy | Kw | R.P.M.* | Measures (in croquis) | |||||||||

| A | B | D | E | F | G | H | L | M | N | |||||

| HT-1000 | 1.205 | 1.000 | 5.5 | 22 | 2000 | 774 | 774 | 152 | 634 | 860 | 1.120 | 2.904 | 220 | 56 |

| HT-2000 | 2.945 | 2.000 | 11.0 | 21 | 2000 | 1200 | 1200 | 239 | 822 | 1.300 | 1.81 | 3.416 | 250 | 180 |

| HT-3000 | 4.653 | 3.000 | 15.0 | 22 | 3000 | 1.250 | 1.250 | 284 | 850 | 1.410 | 1.600 | 3.977 | 250 | 3 |

| HT-4000 | 5.429 | 4.000 | 18.5 | 22 | 3.500 | 1.250 | 1.250 | 281 | 850 | 1.410 | 1.600 | 4.477 | 250 | 190 |

| HT-6000 | 7.131 | 6.000 | 30.0 | 22 | 3.780 | 1.390 | 1.250 | 360 | 890 | 1.510 | 1.795 | 4.939 | 340 | 290 |

measurements in litres

* (KWH)50Hz Motor

* (N) Number of discharge chutes