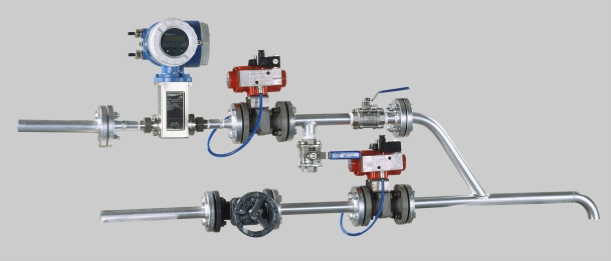

Fat dosing to the mixer/conditioner

GRANULATION CONDITIONER DOSAGE EQUIPMENT

Homogeneous mixing of liquids and solids

The granulation conditioners are merely fast mixers, horizontals and of strong construction and with a predisposition of agitator paddles made to add liquids and steam to the floury or fibrous substances in mixers without lumps to the posterior and appropriate granulation of the mixture. Our dosage equipments of liquids work volumetrically (magnetic-inductive meters). These have been developed for a wide field of applications and dose liquids varying of several viscosities and temperatures. This dose reestablished quantities of liquid and give the constant regulated flux or the flow depending on the product quantity that need to be mixed with the liquid and steam.

The regulation starts when the pilot signal is received by a generator (15) rotational tachometric indicator capable of supplying processable signals from 4 to 20 mA or 0 – 10V depending on rotation speed of granulation dispensing feeder, or is able to determine the machine production or performance in Tn/h.

GENERAL TECHNICAL CHARACTERISTICS:

- Possibility of addition of several liquids, the most common being MOLASSES, VINAZA, etc.

- The possibility of joint dosage steam-liquids (mixing dosage) or separately. Dosage with adjustable and regulable addition temperature with saturated steam or dosage in cold.

- Dosage of liquid atomization (atomized product) if we determine one addition with accompanied steam.

- Optimum dosage between 0,5% and 10%.

- Improvement in the presentation, hardness and quality of granule produced by its perfect homogeneity in the mixing before granulation.

- Possible security in machine production or yield increase (Tn/h.) at entery of liquid in spray form.

CONTROL CABINET FOR MICRO-PROCESSOR

Total automatic control of dosage by microprocessor.

- Solid flow indication Tn/h. machine production.

- Liquid flow indication Kg/h. dosage.

- Liquid preselection in percentages.

- Kg totalization of fluid.

- Equipment for the manual control.

Signal switches and lamps for the control and the checking of function with necessary situations and signal contacts or manufacturing lots for the dosage elements integrated for the different manufacturing processes.