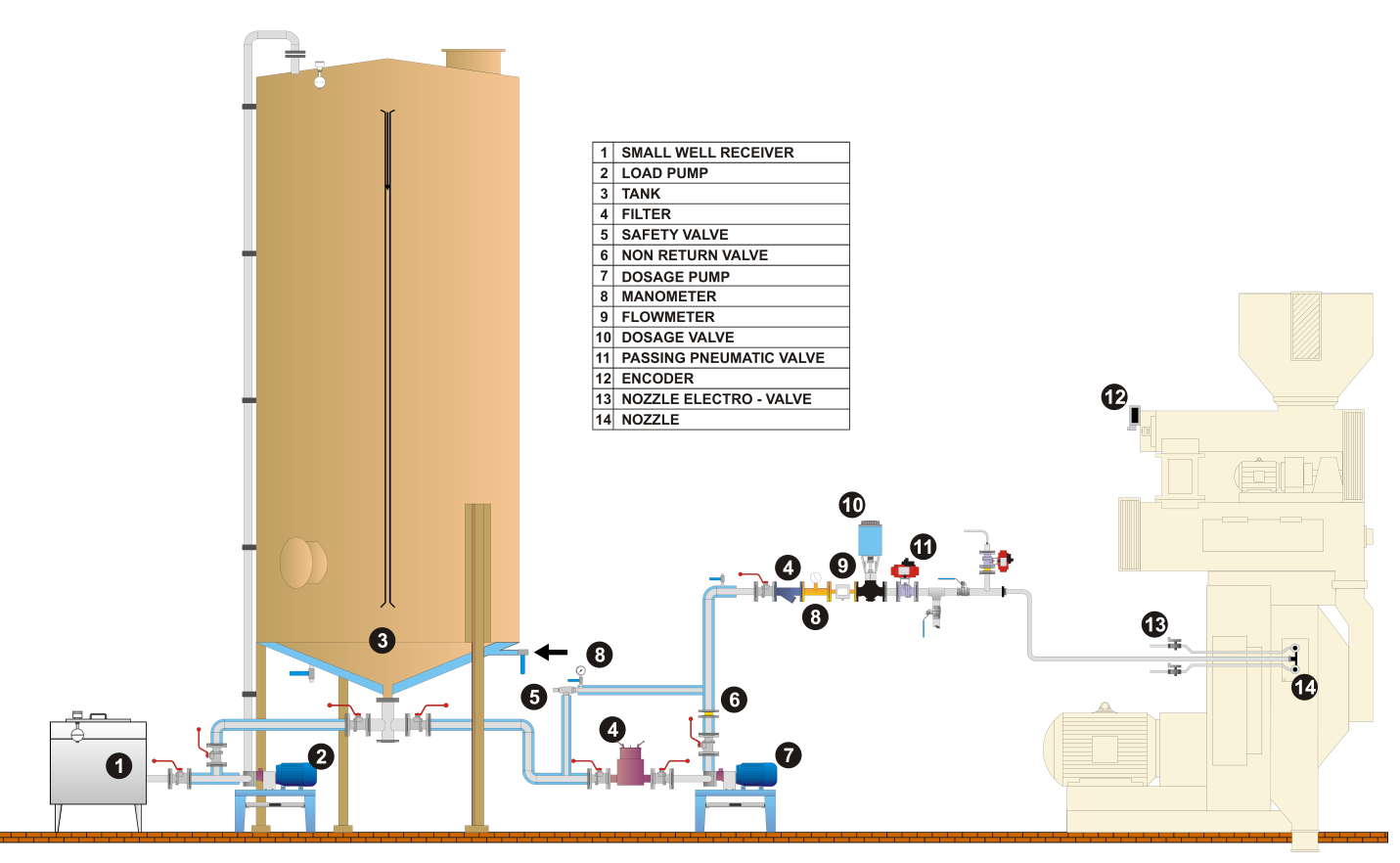

Fat dosing to the pellet press

DOSAGE EQUIPMENT GRANULATION RELUBRICATION DIE IN FAT SPRAY

Fat addition by pulverization

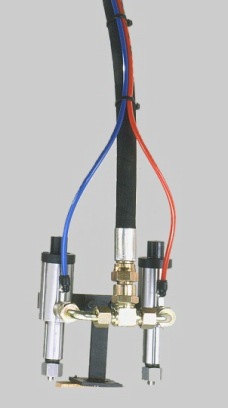

The additional equipment for pulverisation has been made to dose the liquid grease on granules as the leave from the die. This equipment can be adapted to anyone press if there is enough place to install the pulverisation poppet. The pump flow, the recount and the selection of injectors are determined by the press flow and the grease quantity to pulverize on the product. In other words Tn/h. and Kg/min. The characteristics of injectors are determined by press production. The equipment can be used for the different percentage of grease additions, minimum 0,5% to a maximum of a 5%. At this point we must realise the following point, in the practice, the percentage of pulverized grease depends on the three factors: 1st. Size of the granules. 2nd. Absorption ability of granule considering the temperature of the granules as the leave from the die. 3rd. Elaborated quality level of desired product.

GENERAL TECHNICAL CHARACTERISTICS:

Taking advantage of high temperature of the granule extraction at the die, being of the same open texture and in optimum conditions for absorption, we determine the following:

- Optimum dosage between 1 and 1,8% (advisable).

- Improvement on presentation and hardness of granules.

- Increase of grease addition percentages without reducing the quality of granules.

- Improvement of press production due to the use of dies with less compression.

- In smaller percentage (from 1 to 2%) the sliding is made easy in silo in the factory and on the farm.

- Associated to the grease addition in the flours: reduction of die changes (polyvalence of dies for having an inferior compression).

RECOMENDATION TO BEAR IN MIND:

- Possible dirtying of cover the equipments and circuit placed on the following maintenance by cleaning.

- From 4 to 5% of dosages depending on determined products, any provocation of greasing marks on the bags. So we have to add the appropriate percentage.

- Carry out the dosages at high temperatures, or else difficulties will arrive in sliding and risk formation of dough in relation to high percentages.

CONTROL CABINET FOR MICRO-PROCESSOR

- Total automatic control of dosage by microprocessor.

- Solid flow indication Tn/h. machine production.

- Liquid flow indication Kg/h. dosage.

- Liquid preselection in percentages.

- Kg totalization of fluid.

- Equipment for the manual control.

Signal switches and lamps for the control and the checking of function with necessary situations and signal contacts or manufacturing lots for the dosage elements integrated for the different manufacturing processes.